Explosion Proof Lighting Socket 4p+N+PE 5p+N+PE

Basic Info.

| Model NO. | Explosion Proof Plugs and Socket |

| Function | AC Plug |

| Certification | CCC, Atex |

| Application | Power Supply |

| Interface Type | ADC |

| Nominal Voltage | 220V |

| Brand | Atex |

| Degree of Protection | IP65 |

| Operating Temperature | 5ºC~+50ºC |

| Fireproof Grade | Wf2 |

| Nos. of Pole | 1p+N+PE, 3p+N+PE,4p+N+PE,5p+N+PE |

| Transport Package | Carton |

| Specification | 335*125*77MM |

| Trademark | Maxtree |

| Origin | Shanghai |

| Production Capacity | 5000PCS/Month |

Packaging & Delivery

Package Size 1.00cm * 1.00cm * 1.00cm Package Gross Weight 1.000kgProduct Description

Product Description

Explosion-proof plug is composed of plug and socket. The shell is made of die-cast aluminum alloy. The socket is connected to the power supply end, and the plug is connected to the electrical equipment end. toggle switch. Explosion-proof plugs are divided into explosion-proof flameproof plugs and sockets and explosion-proof flowerless plugsExplosion-proof plugs are composed of plugs and sockets, and are mainly used in chemical industry, various mines, petroleum, and places where explosion-proof is required. And subdivided into single phase. For lighting, three-phase, for machine tools and other places.

Key Features1. The shell is made of glass fiber reinforced unsaturated polyester resin pressed or welded with high-quality stainless steel. Itis corrosion-resistant, antistatic, impact-resistant and has good thermal stability.2. Stainless steel exposed fasteners, high corrosion resistance.3. The enclosure is Safety-increasing type with flameproof switch inside.4. Pluas are connected to electrical equipment.5. The socket is equipped with reliable mechanical interlocking device, that is, the switch can be closed only after the pluą isinserted into the socket, and the plug can be pulled out after the switch is disconnected.6. The socket is equipped with a protective cover. After the plua is pulled out, the socket is covered with a protective cover toprevent sundries from.entering7.Steel pipe or cable wiring is acceptable.

Material: glass fiber reinforced unsaturated polyester resin pressed or welded with high-quality stainless steel

Detailed Photos

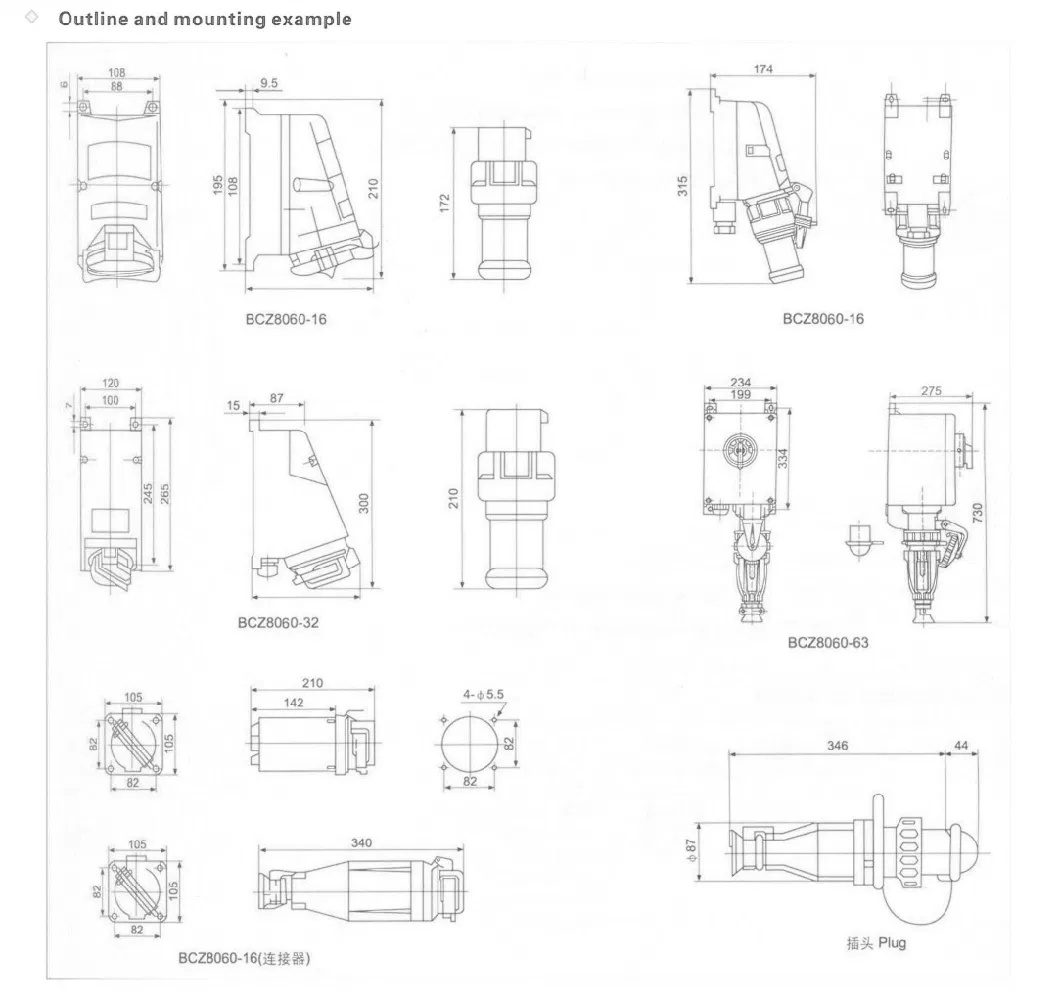

| Models | AC8060-16A | AC8060-32A | AC8060-63A |

| Rated Current [A] | 16 | 32 | 63 |

| The cable for plug | Φ3mm-Φ14mm | Φ11mm-Φ18mm | Φ17mm-Φ28mm |

| Inlet threads | G 3/4" | G 1" | G 1 1/2" |

| Rated Voltage | 220/380VAC | ||

| Nos. of pole | 1P+N+PE, 3P+N+PE,4P+N+PE,5P+N+PE | ||

| Ex rate | Ex d e IIC T4 Gb, Ex tD A21 IP65 T80ºC | ||

| Function | Electrical Outlet Connection | ||

| Degree of protection | IP65 | ||

| Application | Zone 1&2 Zone 21&22 | ||

| Note | linker used for connecting distance-cable, linker current is only limited to 16A. | ||

| Operating Temperature | -5ºC~+50ºC | ||

Application scenarios

Abrasive BlastingAutomotive Repair ServicesChemical PlantsDispensing AreasDistilleriesIndustrial Process FacilitiesRail YardDrilling RigsGranariesWastewater And Sewage PlantGas And Oil RefineriesFood Processing PlantsPaint Booths

1.Why is Explosion Proof Lighting necessary in your area?

Plenty of commercial facilities have areas where lighting fixtures can come into contact with hazardous materials. These can be flammable, combustible, or ignitable materials, gases, or vapors. These areas can be at risk of fire or even explosion if the lighting fixtures can't withstand the abnormal conditions.

2.What is hazardous location lighting?

Hazardous location lighting refers to fixtures that you can safely use in an area where it's likely that fire might start. According to the National Electrical Code, hazardous locations are those areas "where fire or explosion hazards may exist due to flammable gases or vapors, flammable liquids, combustible dust, or ignitable fibers or flyings." 3.What is explosion-proof light fixture?

Explosion proof lighting refers to lighting fixtures that are able to contain sparks that could potentially the flammable and explosive gases in the atmosphere. Therefore, explosion proof lighting does not refer to lighting equipment that are resistant to explosions but rather, the capacity to prevent external explosions from occurring in a hazardous location.

4.What environments require hazardous location lighting?

Presence of Flammable Liquids and GasesWherever flammable gases and liquids are present, the location may be identified as a hazardous one because such compounds can cause an explosion or catch fire.Gas and liquids have to achieve a critical concentration before it becomes dangerous. However, once they do, that's when a potential disaster can occur.

Company ProfileAs a leading supplier of explosion proof lighting,Lamp suite is dedicated to helping you illuminate numerous settings with powerful and durable lighting systems. We've assisted a variety of businesses with projecting sufficient lighting across the work space or public area, including:- Commercial scenes- Government projects- Mining sites- Remote accommodation sites- Warehouses & other industrial environmentsOur explosion proof lighting is designed using technologically advanced methods with both economical and ecological results. Lighting is a crucial aspect of successful workflow and, therefore, your business' profit.Finding suitable lighting for the work site that won't falter under extreme circumstances is what makes it most reliable in any situation. Lamp suite explosion proof lighting is 100% certified with non-spark, durable, and thick materials, along with all necessary features to maintain a high level of safety at all times.

So, what makes Lamp suite different? Our expertise in solar and technical lighting solutions allows us to give you the appropriate explosion proof lighting to suit you and your business's needs the best. As a result, you can expect outstanding LED performance, lower costs, increased productivity, and safety adherence to give you and your workers total peace of mind.